Technical Sanjay Refinery

Hello Friends

Welcome You to all of you

Learn Always Let's Come You and Me.

Construction , NDT & Quality videos available.

Ultrasonic testing acceptance criteria|AWS D1.1/D1.1M:2020

Structural steel fabrication work .

Bolt Tightening By Machine @TechnicalSanjayRefinery

Bolt tightening by Machine | bolting tightening inspection @TechnicalSanjayRefinery

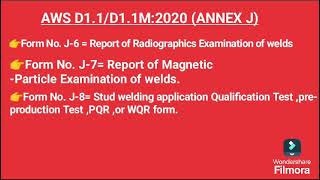

Procedure qualification record|AWs d1.1/d1.1M:2020| steel structure Fabrication

Steel structure fabrication welding

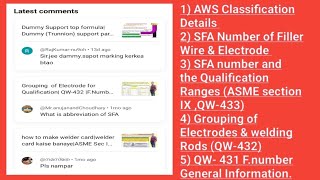

Grouping of Electrodes and Rods for Qualification Welder in hindi |@TechnicalSanjayRefinery

Piping Information|@TechnicalSanjayRefinery

Piping system| Basic of Oil and Gas Refinery #TechnicalSanjayRefinery

Radiography Testing of Welded Material|ASME sec V| procedure|@TechnicalSanjayRefinery

weld visual view

weld visual inspection AWS d1.1 |t 8.3

Preheating Process by preheating burner and Thermo pen |temperature minimum temp 65°C.

Precast H-Frame Assembly for heavy lifting and rigging purpose|@TechnicalSanjayRefinery

structure Column Alignment|water level |plumb check vertically| @TechnicalSanjayRefinery

welding weld visual @TechnicalSanjayRefinery

pre- heating the job |before welding

steel structure work

preheat before the welding|@TechnicalSanjayRefinery

structure Column Alignment| inspection points.

Submerged Arc Welding |SAW | process welding.

Preheating the joint | metal thickness above 25 mm

Fillet Weld Gauge | welding Gauge in Hindi

welding position|ASME section ix QW-460.9|@TechnicalSanjayRefinery

Root Weld in plate 300x230x16 mm |@TechnicalSanjayRefinery

root welding defects|@TechnicalSanjayRefinery

dye penetrate testing of butt joint |Acceptance Standard ASME section viii div.I Appendix 8

Welder Test Position Qualification| ASME Section IX |QW-461.3 in Hindi

Groove Weld in Pipe Test Positions|ASME section IX QW-461.4

Welder thickness ranges | thickness qualification ranges | @TechnicalSanjayRefinery