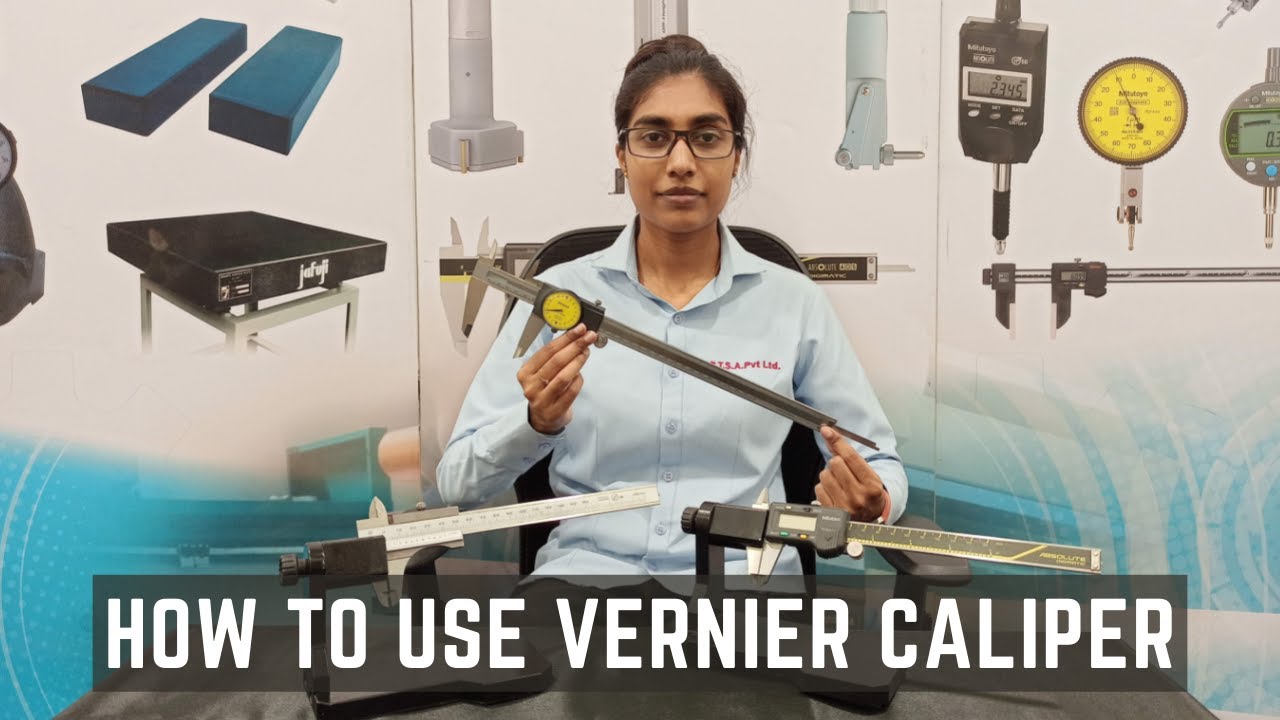

How to use Vernier Caliper | Bombay Tools Supplying Agency Pvt Ltd

Автор: Bombay Tools Supplying Agency Private Limited

Загружено: 2021-06-15

Просмотров: 9374

Video Description

In this vlog, we will be discussing the various tips and the right way to use a caliper.

In machine shops, the term "caliper" is often used when compared to a "micrometer". There are various types of calipers, but all are designed in the same way.

A variety of factors can cause errors when measuring with a caliper. Major factors include parallax effects, excessive measuring force because a caliper won’t conform to Abbe’s principle, differential thermal expansion due to a temperature difference between the caliper and workpiece, the effect of the thickness of the knife-edge jaws, and the clearance between these jaws during measurement of the diameter of a small hole. Although there are also other error factors, these factors are included within the instrumental error tolerances.

What is ‘parallax error’?

Parallax is a displacement or difference in the apparent position of an object viewed along two different lines of sight, for example, our eyes have different lines of sight while viewing the same object. The process by which the brain exploits the parallax is due to the displacement caused in the apparent position of the object due to the viewing angle, i.e., other than the angle that is perpendicular to the object.

When reading the scale, look straight at the vernier graduation line when checking the alignment of vernier graduation lines to the main scale graduation lines. If you look at a graduation line from an oblique direction (A), the apparent alignment position is distorted by Δx as shown in the figure. This effect is caused by the step height (H) between the planes of the vernier graduations and the main scale graduations, resulting in a reading error of the measured value. To avoid this error, the step height should not be more than 0.3 mm.

Initially, we are going to check the zero measurements. When we close our jaws, we can see some gap, don’t measure that, the closed portion is the jaw area which we should measure.

Always use constant Force. Too much of force can damage the part and too little force gets insufficient contact with the part to be measured and gives a wrong measurement. If the moving jaw becomes tilted out of parallel with the fixed jaw, either through excessive force being used on the slider or lack of straightness in the reference edge of the beam, the measurement error will occur as shown in the figure.

While taking measurements, make sure that measurements are not taken on the edge of the jaws. Instead, take a measurement on the machined area and preferably on the top which will give better consistency, accuracy, and repeatability. Clean the contact points or the jaws using a lint-free cloth before measuring. We can also grip a lint-free paper between the outside jaws and slowly pull it out. Now close the jaws and see towards the light and make sure that light does not pass through the jaws. If light passes through, there may be a parallelism error that has to be repaired. In Internal Jaws a small amount of light will be shining through, and the edges should be clean without burs. Ensure that the sliding jaw moves smoothly over the length of the beam. We can use the plastic or the roller to roll over the beam and make sure the force is constant. Due to step-in height of the vernier scale relative to the main scale, if the viewing direction is not directly above the reading, we may have a parallax error. Initially set the zero setting of the caliper to avoid abrupt errors.

Please follow the video to see how to take a reading on a metric vernier caliper.

Now please follow the video on how to take the value on a Dial Caliper.

Let’s now measure the same component using a Digital Caliper.

Avoid damaging the scale of a digital caliper and do not engrave anything on it with an electric marker pen. Avoid damaging a caliper by subjecting it to impact with hard objects.

If the caliper is not going to be used for a longer period, remove the battery and do not leave the jaws of the caliper completely closed during storage.

Bombay Tools Supplying Agency Pvt. Ltd is a leading precision measuring instrument supplier in India since 1942. Reach out to us for any of your precision measurement instruments requirements. Visit our website to know more - https://btsa.in/

Disclaimer :

Under no circumstances will Bombay Tools Supplying Agency Pvt. Ltd. be responsible or liable in any way for any content. Including but not limited to, any errors or omissions in the content, or for any loss or damage of any kind incurred as a result of any content communicated on this youtube page, whether by Bombay Tools Supplying Agency Pvt Ltd or a third party. In no event shall Bombay Tools Supplying Agency Pvt Ltd be liable for any special, indirect, or consequential damages or any damages whatsoever resulting from loss of use, data, or profits arising out of or in connection with the availability, use, or performance of any information communicated on this youtube page.

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: