How To Set up a Regulator for Carbon Dioxide Delivery

Автор: DeBacco University

Загружено: 2021-05-20

Просмотров: 8152

How To Set up a Regulator for Carbon Dioxide Delivery

Professor DeBacco

Function of a Regulator

To deliver the actual CO2 at a fixed flow rate.

*The controller determines the frequency and duration of the delivery.

For simplicity the regulator that would be attached to a compressed CO2 bottle will be used as a model for comparison.

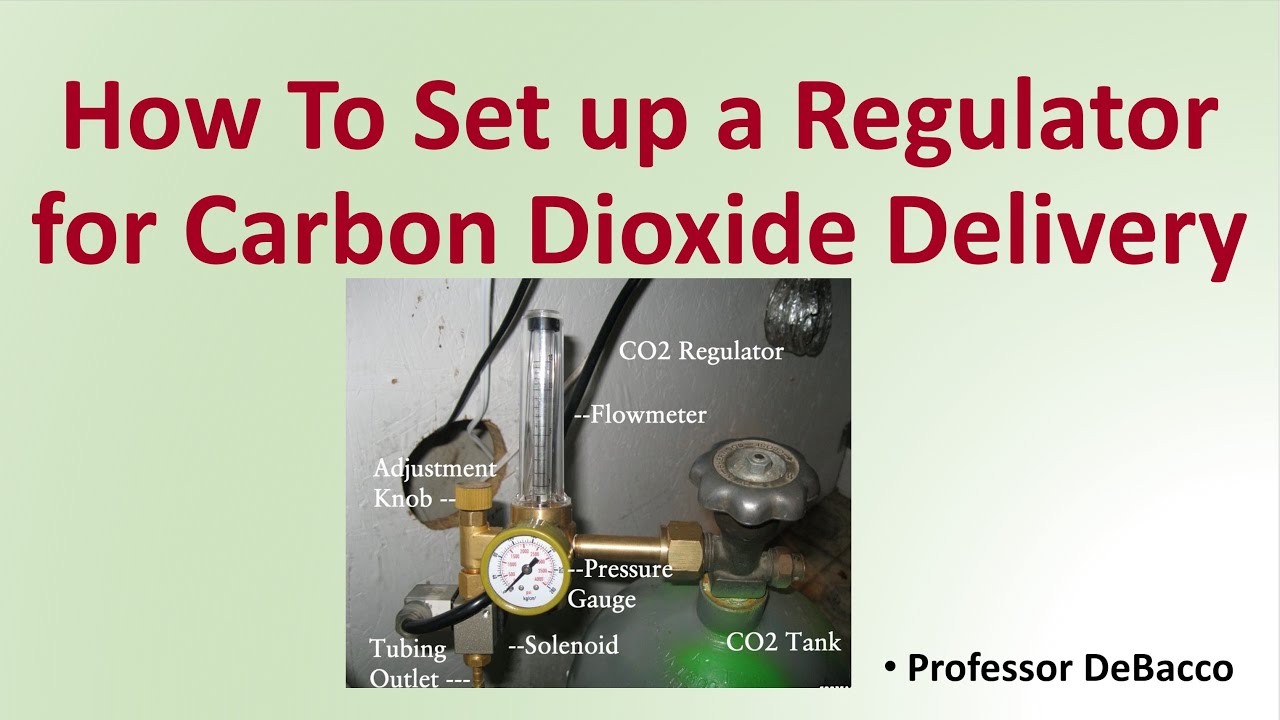

Components of a Regulator

Attachment Nut (with washer inside)

Extra washers

Bottle pressure gauge

Flow Rate

Flow Adjustment knob

Actual on/off electronic valve

Power cord goes to controller

Dispensing point for CO2

Importance of the Washers

Have extras and replace as needed

Once Connected and Tightened…

Read over the regulators instructions but typically…

Once all systems are all set-up you can turn on the CO2 bottle by slowly rotating the top valve.

Avoid just opening up the valve and the CO2 rushing into the closed valve as this could damage critical internal components.

You will know the system is pressurized when the gauge provides a pressure reading.

For a full bottle the pressure should be around 1000psi (or about 7000kPa)

How To Check For Leaks

Once pressurized you should listen carefully for any potential leaks

The system should be silent

(unless dosing)

Even if you hear a slight hissing sound investigate all connections.

Listen carefully to all areas of the valve and if you can not determine the exact area there is a trick…

Soapy water

Soapy Water

If you suspect the regulator (or some other part of the CO2 system has a leak take some water and add liquid soap to it.

You want a level where bubbles will easily form in the soapy water solution.

Then take this soapy water solution and apply it to the regulator.

If air is leaking you will see small bubbles forming pinpointing the area of the leak.

Adjustments to Make

Regulating the flow rate can depend on the size of the growing space.

Running the flow rate too high in a small grow space will cause large swings in CO2 levels and make it difficult for your controller to regulate the levels.

Running the flow rate too slow will cause the target levels not to be reached for the grow space.

*Do not go above 10cfm (cubic feet per min.) as this may cause the regulator to freeze up.

Regulator Freeze-up

This occurs when the flow rate of CO2 is too fast as there is a cooling effect.

The CO2 is cold when it goes from the compressed to uncompressed state.

This can happen even in hot grow spaces.

If there is a problem with your regulator and the valve gets stuck open it can cause the bottle to empty quicky resulting in a frozen regulator.

Suggested Flow Rates per Grow Space

Link to Lecture Slides: https://drive.google.com/file/d/16RK4...

420 Magazine Source Content by Slide Title:

Title: How To Set up a Regulator for Carbon Dioxide Delivery

https://www.420magazine.com/community...

*Due to the description character limit the full work cited for "How To Set up a Regulator for Carbon Dioxide Delivery" can be viewed at... https://drive.google.com/file/d/1ePkj...

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке:

![Адаптер для баллона CO2, фитинги CO2 и описание баллонов CO2 [CryoFX]](https://image.4k-video.ru/id-video/iuoVLsuuKcI)