331. THIS is why your acrylic jig broke

Автор: Make Things

Загружено: 19 апр. 2025 г.

Просмотров: 22 986 просмотров

At some point, you’re gonna need a clear window to see what you’re doing. Maybe it’s a router base, maybe a jig. But either way—it doesn’t make sense if you’re flying blind.

So you grab some clear plastic… right?

Hold up.

Not all clear plastic is equal—grab the wrong kind, and it’ll crack, melt, or flex like jelly.

There are a few options to look at.

Polycarbonate, while tough, scratches easily and is going to be the least clear of our clear plastics. It bends instead of breaking, which sounds great—until your router base flexes mid-cut. It’s not rigid enough for jig work.

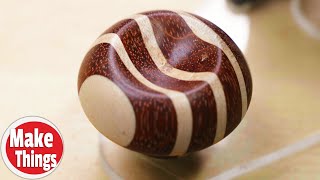

Acrylic, our next option, is going to be the clearest plastic, but it’s tricky. There are two types: Cast and Extruded. Extruded is far cheaper, but it’s shockingly brittle under drill pressure—especially in jig work. Machining it to shape can cause it to crack. It works for crafts—not for tools.

Cast, created by pouring acrylic into molds and curing it slowly, is what you actually want. It’s rigid, cuts clean, and holds up to drilling and vibration. And it stays clear.

The most frustrating part? Some distributors won’t even label which type it is. So if the label doesn’t say “cast,” it probably isn’t.

Got a tip, send me an email (and get credited)! → [email protected]

Check out my other channel! → @makethingswithrob

Become a patron! → / makethings ←

Huge thank you to my patrons that keep this thing going!

MAKER TEAM

Michelle B

Keith Current

William L McNally

Rich Lightfoot

Tutor the Barbarian

Aubrey G.

Nukebert

Sam W.

Aaron Knows DIY

G. Salazar

David B.

Make Things

#MakeThings #mtbitesize

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: