CSP Chapter 12 | Fire Prevention & Protection: The Science That Stops Fires Before Ignition

Автор: QHSE Talks

Загружено: 2026-01-07

Просмотров: 93

Welcome back to QHSE Talks, where we break down essential safety concepts and regulatory frameworks that every safety professional and engineer must master. In this episode, we dive deep into Chapter 12: Fire Prevention and Protection, focusing on the technical foundations required to prevent fire incidents and protect personnel, property, and processes. Whether you are preparing for OSHA 10, OSHA 30, or seeking to implement ISO 45001 safety management systems, understanding fire hazards, regulatory standards, and protective measures is non-negotiable.

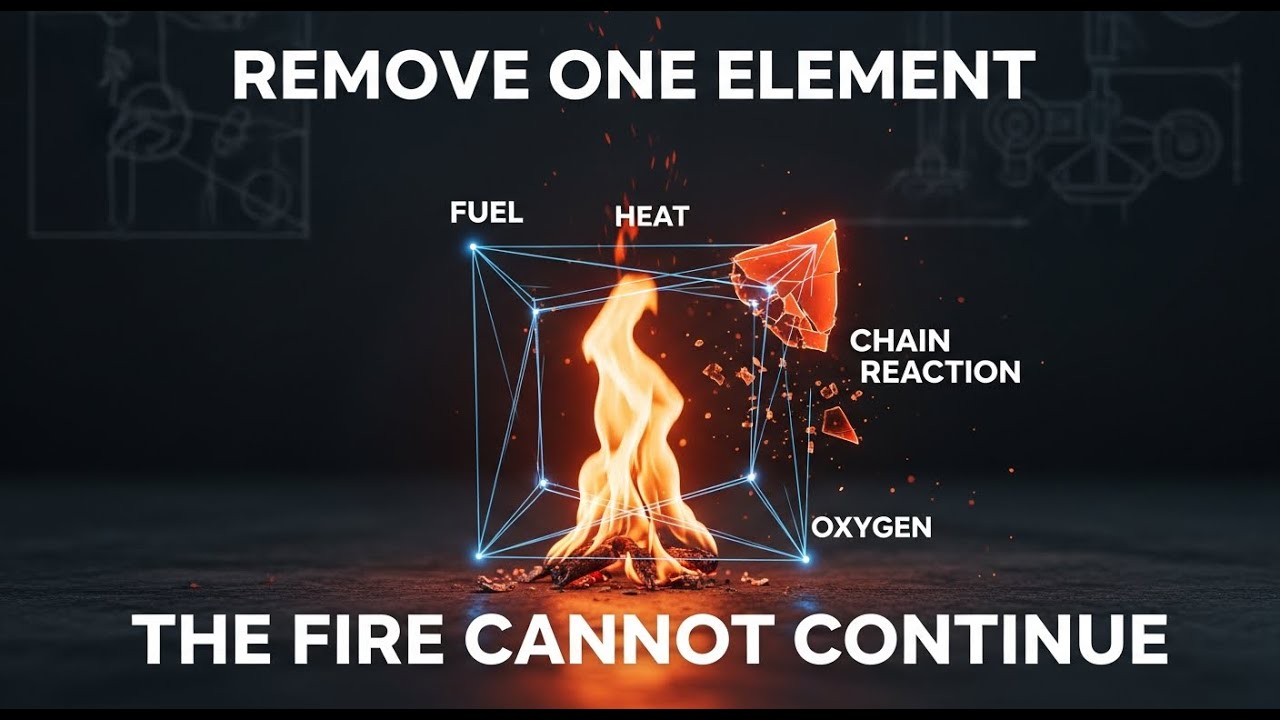

Fire is not an accident; it is a predictable chemical reaction governed by physical laws and regulatory thresholds. Fires develop when fuel, oxygen, heat, and a continuous chemical chain reaction align—the elements of the Fire Tetrahedron. By removing just one element, fires cannot sustain themselves. This concept is crucial for safety professionals designing fire prevention strategies, managing hazardous chemicals, or developing emergency response plans.

This episode begins with a comprehensive discussion of heat transfer mechanisms, which play a critical role in fire propagation. Heat spreads through conduction, convection, and radiation, and understanding how energy moves in your facility is essential for engineering controls, layout design, and risk assessment. Every facility, from industrial plants to commercial kitchens, must consider these principles to prevent fires before they start.

We also cover the NFPA fire classifications (A, B, C, D, K), helping you identify the type of fuel involved in a fire scenario. Correctly classifying hazards ensures the right suppression systems are selected. For example, Class A fires involve common combustibles like wood and paper, whereas Class B covers flammable liquids, and Class K is specific to cooking oils and fats. Misclassification can lead to ineffective fire suppression, increased risk, and compliance violations under OSHA and ISO 45001 standards.

Fire suppression systems are a cornerstone of protection. In this episode, we explain both portable and fixed systems. Portable extinguishers are rated for coverage and must be inspected monthly, serviced annually, and hydrostatically tested at prescribed intervals. Automatic sprinklers come in various designs, including wet pipe, dry pipe, deluge, and pre-action systems, each suited to specific hazards. Choosing the correct system aligns with NFPA standards and reduces fire-related risks while maintaining compliance with OSHA regulations.

Detection and monitoring are equally critical. Heat detectors respond to temperature thresholds or rate-of-rise, while smoke detectors use ionization or photoelectric technologies. Early detection gives personnel and safety systems the time to act before fires escalate, reinforcing the principle that prevention is always better than response. Fire hydrants, color-coded for flow rates, also provide active protection and support emergency preparedness plans.

A major focus of this episode is the properties of flammable and combustible liquids, which are often overlooked in workplace safety programs. Understanding flash point, flammability limits (LFL/UFL), autoignition temperature, and vapor density allows safety professionals to implement proper ventilation, storage, and PPE selection. For instance, a vapor heavier than air can accumulate in low-lying areas, creating a hidden hazard if not properly ventilated or monitored. These chemical properties are central to hazard identification and risk management, key elements of OSHA 10 and OSHA 30 training, as well as ISO 45001 safety management systems.

This video is designed for safety professionals, engineers, and anyone pursuing certifications such as OSHA 10, OSHA 30, CSP, ASP, or involved in ISO 45001 implementation. By combining regulatory knowledge with practical engineering insight, you will gain the tools to predict, prevent, and control fire hazards in any facility.

Key topics covered in this episode:

Fire Tetrahedron and the elements required for combustion

Heat transfer mechanisms: conduction, convection, and radiation

NFPA fire classifications: Class A, B, C, D, K

Portable and automatic fire suppression systems

Heat and smoke detection systems

Storage requirements, ventilation, and regulatory compliance

Integration of PPE, engineering controls, and administrative safeguards

By mastering these fundamentals, safety professionals can eliminate preventable fire hazards, ensure regulatory compliance, and protect lives and property. Remember, the most dangerous fires often start long before flames are visible, and prevention is always more effective than response.

Stay tuned, subscribe to QHSE Talks, and ensure your workplace is safe, compliant, and prepared.

#OSHA #OSHA10 #OSHA30 #FireSafety #Safety #PPE #Hazard #NFPA #FirePrevention #IndustrialSafety #WorkplaceSafety #FireProtection #CSP #ASP

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: