Precision Laser Cutting

Автор: Gear Quest

Загружено: 2023-12-25

Просмотров: 4770

Deep in the Tayma Oasis in Saudi Arabia’s Tabuk province lies a 4,000-year-old rock formation with an unusual feature. It is split down the middle by a straight cut with the precision of what some believe to be a laser.

The Al Naslaa rock is composed of two sandstones supported by a naturally-formed pedestal with a perfect slit down the middle.

While the exact cause of the split has yet to be determined, windblown sand and periodic rain could have created the unusual shape.

Some even suggest the desert’s ancient inhabitants cut the rock in half using a lost ancient technology of laser beams.

Wherever the truth lies amongst the theories, the precision of the cut is eerily similar to what modern cutting techniques could produce.

Other examples of precision cutting in the ancient world that we definitely know are the results of human effort can be seen in Egypt.

A prime example of this exists in the ancient northern region of the stone quarries in Aswan, Egypt. The object is an ancient unfinished obelisk, considered by experts to be the largest known one of its kind.

The obelisk and wider quarry were inscribed on the UNESCO World Heritage List in 1979 along with other examples of Upper Egyptian architecture.

Its creation was ordered around 1508 to 1458 BC, to possibly complement what would later be known as the Lateran Obelisk. The unfinished obelisk is nearly one-third larger than any ancient Egyptian obelisk ever erected. If finished it would have measured around 41.75 meters or 137 ft.

Based on archeological findings, the obelisk's creators began to carve it directly out of bedrock, but cracks appeared in the granite and the project was abandoned. The bottom side of the obelisk is still attached to the bedrock.

The unfinished obelisk offers unusual insights into ancient Egyptian cutting techniques, with marks from the workers' tools still clearly visible as well as colored markings left behind from where they were working.

As far back as humans existed, the need to cut materials with precision has always been a necessity. And the techniques applied have only been improved over the course of time.

In the case of the ancient Egyptians, the use of hammers and chisels was instrumental in cutting a series of holes in an extracted block of stone. Then water-soaked wooden wedges were inserted into the holes, where they expanded and split the rock. Other cutting techniques involved the use of copper saws along with sand and even bronze tools that were used with limestone and other softer rocks. These are just some of the many techniques applied to accomplish the task.

The precision-cutting techniques of modern times have negated the need for such manpower, allowed for the cutting of various materials, and reduced the time it would take to accomplish such a feat when compared to ancient times.

At this point let’s talk about two popular modern cutting techniques that offer such precision.

Laser and Plasma Cutting Introduction

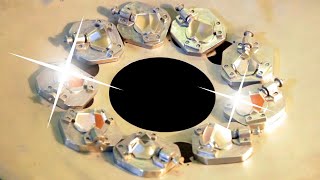

Laser and plasma cutting are both methods well-suited to the CNC (Computer Numerical Control) machining production process. These technologies are thermal processes commonly used in industrial settings to cut materials. The main difference between the two technologies lies in the source of the technology's cutting power: laser cutting machines use a narrow and intense ray of light to cut through materials. This is in contrast to plasma cutters which use a device for generating a directed flow of plasma for cutting.

Laser cutting can be used to cut a wide range of materials, including ceramic, wood, plastics, and metals. This is a stark contrast to plasma cutting which can only be used to cut conductive materials. Laser cutting is faster, more accurate, and produces a better surface finish than plasma cutting. The laser method is also better suited for making intricate cuts than plasma cutting. On the other hand, plasma-cutting machinery requires less maintenance and is less costly than laser-cutting equipment. Both technologies are mainly used to cut metals, although laser cutting is also commonly used for other materials as well.

Selecting between the two CNC cutting processes can depend on many factors. In this video, we will compare laser cutting and plasma cutting in terms of speed, materials, cost, and other factors that distinguish these two techniques.

Laser cutting works by directing the highly concentrated energy of a laser beam onto a material, producing local melting and separation of the workpiece. Depending on the details of the cutting technique, the laser may melt the material, with an assistive gas stream blowing the melted material out of the way. Or it may directly change the cut material from solid form to gas; also known as sublimation, with the kerf removed in vapor form. Kerf is the width of a cut. It is the result of material removal during the cutting process. Laser cutting equipment can cut structural and pipe materials as well as thin sheets.

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: