Design for Manufacturing Course 11 Part 2: Boothroyd Dewhurst Method - DragonInnovation.com

Автор: Dragon Innovation

Загружено: 2014-12-08

Просмотров: 16360

http://www.dragoninnovation.com

In this Design for Manufacturing lecture, we are focus on the Boothroyd Dewhurst Method of Design for Assembly. Much of the inspiration for this lecture comes from the following references.

Product Design for Manufacturing and Assembly

Designing Plastic Parts for Assembly

There are several other methods besides Boothroyd Dewhurst when looking at Design for Assembly but it is by far the most popular and wide-spread. The operating thesis behind this method is that the product cost is directly related to the assembly time so if you can put it together quicker, there is less of a labor rate. Additionally, the assembly time and quality are directly related to both the part count and the ease in which the parts go together.

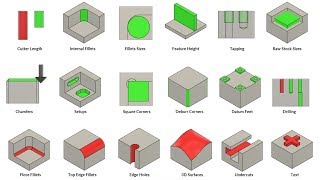

The Boothroyd Dewhurst Method involves systematically looking at the part geometry and how they're fastened to estimate a time to put the different parts together. Then, adding it up and comparing it to a theoretical minimum part count (what's the fewest number of possible parts you could have to build the product). You will then get a ratio of the two to get an overall design efficiency. The actual number does not matter as it's intended as a benchmarking tool; as you improve the design you have some benchmarks or some comparison points so you know this design is better or worse than that your previous design.

Most importantly, this method forces you to take a step back because everything is so rushed to get the actual product working and you're thinking about so many things. The Boothroyd Dewhurst method lets you pop up a level and think specifically about assembly and ask questions: Do I really need two parts? Can I put them together with snap fit rather than screws? It is those key insights that are important.

Read more on this video: http://blog.dragoninnovation.com/2014...

Download the SlideShare presentation: http://www.slideshare.net/dragoninnov...

Learn more about Design for Manufacturing: http://blog.dragoninnovation.com/cate...

About Dragon Innovation:

Dragon Innovation works with entrepreneurs to launch hardware products and scale companies. Founded by a team of hardware experts, Dragon provides a clear path from prototype through production with unmatched manufacturing expertise and trusted connections. Dragon's client roster includes Coin, MakerBot, LIFX, Scout, Romotive, Sifteo, Orbotix, FormLabs and over 100 more companies paving the road for how new technology gets made.

Connect with Dragon Innovation

Website: http://www.dragoninnovation.com

Blog: http://blog.dragoninnovation.com

Twitter: / dragoninnovate

YouTube: / @dragoninnovationinc

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке:

![A Crash Course: Bill-Of-Materials (BOM) // Scott Miller, Dragon Innovation [FirstMark's Hardwired]](https://ricktube.ru/thumbnail/GJAZtfoVA28/mqdefault.jpg)