Flex PCB Design Guidelines for Manufacturing | Webinar Teaser | Sierra Circuits

Автор: Sierra Circuits

Загружено: 2021-02-09

Просмотров: 1337

The advancement of flex PCBs offer many advantages for both the physical designer and the manufacturer. The ability for the PCB to be molded and bent without breakage can lead to smaller designs that are lighter and take up less space all while resisting vibrations and other disruptions from its environment. Furthermore, they allow better airflow, heat dissipation, lower assembly costs, and a reduction in assembly errors.

Watch the full webinar:

https://www.protoexpress.com/webinars...

In order to benefit from all that flex PCBs have to offer, you must have a clear vision of the printed circuit boards functionality, familiarize yourself with the design rules and follow strict guidelines.

Join us to learn how to get started - or improve - your flex PCB designs.

What you will learn:

Benefits of flex PCBs

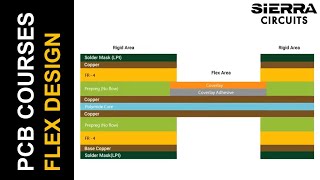

Understand flex materials and how they will impact your board's flexibility

Common guidelines such as stack-up, annular rings, trace routing, and stiffeners

DEMO: How to apply these guidelines during your design process by leveraging cross sections, constraints, and a 3D canvas

Checklist for manufacturing including drawing requirements and fab notes

*******************************************

THE PCB DESIGNER'S CORNER

PCB forum SierraConnect:

https://sierraconnect.protoexpress.co...

Seminars and webinars:

https://www.protoexpress.com/events/?...

Design guides:

https://www.protoexpress.com/pcb-desi...

PCB design tools:

https://www.protoexpress.com/tools/?u...

Sierra Circuits products and services:

https://www.protoexpress.com/products...

Follow us on LinkedIn:

Amit Bahl, the PCB Guy: / amit-bahl-sierra-circuits

Sierra Circuits: / sierra-circuits-inc

SierraConnect: / sierraconnect

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке:

![[LIVE] How to Achieve Proper Grounding - Rick Hartley - Expert Live Training (US)](https://ricktube.ru/thumbnail/ySuUZEjARPY/mqdefault.jpg)