Complete Automation of a Complex Unitizing Process | An MMCI Robotics Case Study

Автор: MMCI Automation

Загружено: 2019-01-23

Просмотров: 3775

#MMCI #automation #robotics #roboticpalletizer #roboticpalletizingsystems

Preparing hot, 30-pound aluminum ingots for storage is challenging work, but it’s even harder when you have to deal with outdated equipment that runs too slowly and breaks too often. Such was the case for this client, a major recycler of aluminum for the automotive industry.

MMCI was challenged to develop a strong and rugged end-of-line packaging solution that could align the ingots, stack them, weigh them and then bind them for transport and storage. Plus, the system would need to operate at a much faster speed than the current system and withstand the high temperature environment.

After evaluating the entire process, MMCI engineers determined that they could design a robotic unitizing cell featuring a Fanuc M410ic robotic arm along with innovative upstream and downstream solutions.

In order to increase the system’s capacity, MMCI had to first optimize the upstream process. The ingots entered the system from a cooling bath and then needed to be aligned for stacking. This was an engineering challenge since the placement of the trapezoidal shaped ingots would have to alternate for each row.

To accomplish this, MMCI engineers developed an inline system that would center, flip and align each layer of ingots for transfer by the robotic arm. The system features a rugged chain conveyor with a smooth, consistent surface that allows the ingots to accumulate at the end of the line. The team then created individual processes for centering, flipping and aligning the ingots on the fly - significantly increasing the system’s capacity.

Next, our design team had to install high tech laser sensors instead of standard customary sensors in order to detect the reflective nature of the aluminum ingots and accurately communicate their position to the robot.

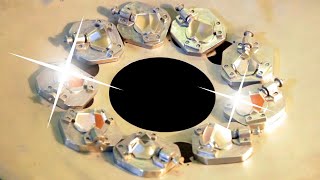

We then configured the robot’s end-of-arm tooling with 3 independently actuated grippers and custom channels that ensure the proper transfer and stacking of each ingot.

Once the ingots are stacked, they move to an inline scale that calculates the exact weight of the unitized load and outputs a label with this information.

To further optimize the downstream process, MMCI Engineers developed automation to replace the manual strapping process currently employed. By integrating an inline strapping machine with a lift, turn table and multiple controls, our team was able to completely automate the strapping process. Multiple sensors were utilized to ensure that all straps are properly positioned to align with notches on the ingot.

Finally, to ensure the cell would run efficiently in the hot, industrial environment, the robot was outfitted with a protective suit and monitored with inline temperature probes through a climate-controlled cabinet certified to 120 degrees Fahrenheit.

With the new automation, loads are being unitized fast enough to keep up with production while the rugged design and protective features have virtually eliminated downtime. Plus, the inline weighing and strapping processes have helped improve efficiency and reduce costs.

This project represents another example of how intelligent engineering and a focus on automating an entire process yields game-changing results for our clients.

At MMCI, our people are experts in Material Handling Automation and are passionate about solving problems of all shapes and sizes. We use over 35 years of experience in design, engineering, integration, robotics, controls and software to deliver automation solutions that improve performance and increase productivity for manufacturers, e-commerce and distribution companies large and small.

We are an engineering service company and we believe that excellent service stems from a culture where people do the right thing, care about delivering great results and take pride in what they do. It is what we believe and what we live for every day.

We can help. If we haven't had the opportunity to work together yet, let us provide you with a quality, value-based bid on your next project.

At MMCI, our people are experts in Material Handling Automation and are passionate about solving problems of all shapes and sizes. We use over 35 years of experience in design, engineering, integration, robotics, controls, and software to deliver automation solutions that improve performance and increase productivity for manufacturers, e-commerce, and distribution companies large and small. We offer solutions in areas like:

-Automation

-Order Fulfillment/Distribution

-Robotics

-Integration

-Warehouse Execution Software (WES)

-Warehouse Management Software (WMS)

-Inventory Management

-Order Management

-Order Picking & Packing

-Conveyor Systems

-And more...

Call us ↓

314-438-3300

Visit our website ↓

https://www.mmci-automation.com/

Tour our Technology Center ↓

39 Worthington Access Drive

St. Louis, MO 63043

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: