Afinitas Prima Wetcast Automation System

Автор: Afinitas

Загружено: 2021-10-07

Просмотров: 3454

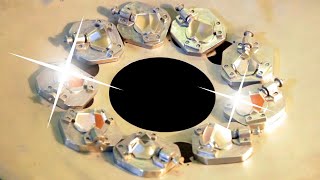

Learn about Prima from Afinitas. Prima is a cutting-edge wet cast automation system designed to drive productivity and bring assembly-line efficiency to wet cast production. With a state-of-the-art production loop, automatic inventory management system, and real-time analytics, Prima reduces labor, increases throughput, simplifies production planning, and provides management with all the metrics they need to optimize their processes at every level. The Prima system is comprised of three unique stages: inventory, outfeed, and production. Fully cured products are automatically delivered from the inventory area to the production loop. Finished components are removed from their forms and sent through the outfeed line for post processing. The empty forms then travel through the production loop to a series of specialized workstations before being refilled and returned to the inventory area for curing. Prima simplifies wet cast production and optimizes throughput by eliminating wasted motions and allowing employees to remain stationary and focus on a single task. With this ultra-efficient design, Prima reduces labor by up to 50% over traditional wet cast production methods.

That means that five to seven direct personnel can deliver between 90 and 100 precast components in a single eight-hour shift.

Now let’s take a closer look at each stage of the Prima production loop.

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: