Water Jet Machining | WJM | Working Principle | Parts | Modern Machining Processes | Hindi Lecture

Автор: Upendrakumar malla

Загружено: 2024-10-14

Просмотров: 910

Water Jet Machining | WJM | Working Principle | Parts | Modern Machining Processes | Hindi Lecture

PPT Link👇👇

• Water Jet Machining PPT | WJM | Working Pr...

Hi This is Upendra Kumar Malla. Welcome to my channel .I wanted to provide some basic information about Mechanical engineering and Industrial safety .

Watch 1200+ latest videos in playlist ( / @upendrakumarmalla ) those videos may use full to you.

Telegram group link 👇👇

https://t.me/+-wAe_ofdt28yZmJl

App link -Google play store link

https://clpdiy17.page.link/6eZ4

For Desktop / Web access -

web link : https://web.classplusapp.com/login

Org code: arfxv

Water Jet Machining (WJM) is a non-traditional machining process that uses a high-velocity jet of water, often mixed with abrasive particles, to cut, shape, or clean materials. It is a versatile method capable of working with a wide range of materials, including metals, composites, plastics, ceramics, and even food products.

The working principle of Water Jet Machining involves the following steps:

Water supply: A high-pressure water pump generates a stream of pressurized water. The pressure is typically in the range of 30,000 to 90,000 pounds per square inch (psi). The water is filtered and conditioned to ensure a clean and consistent flow.

Mixing abrasive particles (optional): In some cases, abrasive particles such as garnet or aluminum oxide may be added to the water stream to enhance the cutting ability. The abrasive particles are mixed with the water in a chamber before entering the cutting nozzle.

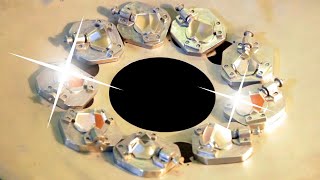

Cutting nozzle: The water, with or without abrasives, is directed through a specially designed cutting nozzle. The nozzle has a small orifice, typically ranging from 0.005 to 0.040 inches in diameter, which helps in achieving high velocities and focusing the jet.

Jet formation and acceleration: As the water exits the nozzle, it forms a high-velocity jet due to the pressure generated by the pump. The jet accelerates to speeds ranging from 600 to 1,000 meters per second, depending on the pressure and orifice size.

Material removal: When the high-velocity water jet impacts the workpiece, material removal occurs through two primary mechanisms:

Erosion: The kinetic energy of the water jet erodes and removes the material by physically washing away particles from the surface.

Abrasion (if abrasive particles are used): The abrasive particles suspended in the water enhance the cutting ability by adding a mechanical cutting action. The particles impact the workpiece surface, abrading and cutting the material.

Controlling the jet: The water jet can be controlled and manipulated using computer numerical control (CNC) systems. The CNC system guides the jet along the desired cutting path, allowing for precise control and complex shapes to be achieved.

Water Jet Machining offers several advantages, including:

Versatility: It can cut a wide range of materials, including heat-sensitive or brittle materials.

No heat-affected zone: The process is non-thermal, meaning it does not generate heat, reducing the risk of material distortion or damage.

High precision: It can achieve tight tolerances and intricate shapes with smooth edges.

Environmentally friendly: It does not produce hazardous fumes or waste, and the water can be recycled.

However, Water Jet Machining may have limitations in terms of cutting speed and thickness of materials. Additionally, the use of abrasive particles can lead to nozzle wear over time, requiring periodic maintenance.

Water Jet Machining finds applications in various industries, including aerospace, automotive, electronics, stone cutting, food processing, and art industries. It is used for cutting materials like metal sheets, composites, stone, glass, foam, rubber, and more.

#modernmachine #modernmachining #machining #productiontechnology #electricdischargemachining #machiningbasics #compitativeexams #mechanicalengineering #milling #drilling #advantages #edmworking #machineparts

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: