1984-86 Honda C70 Street CUB low-and-slow Build P35: Further assembly of the engine. Looking good!!!

Автор: Abandoned

Загружено: 21 апр. 2025 г.

Просмотров: 204 просмотра

Today: more assembly, engine slowly getting ready....very slowly :-)

Videos in the past:

Please comment:

I put a washer below both gear shafts as well below the kick start. Is that correct? Please see in the video :-)

(3 washers in total, all very thin washers, all fitting seemingly well, all is turning nicely)

The engine is a type of C70E - nothing (space is empty) (not like my other 2 engines, which are C70E - M)

Engine Number is 8.4xx xxx (8 (Million) xxx xxx)

Cases ready for assembly!!

finalised machine polishing as good as I can do it.

Sorry the iPhone batterie died before the vid was done.

Bolted the casing onto a cupboard and polished away.

Fine polish in the nooks still to be done.

Hard Work, but hey ho :-)

As there were more than 8 Million of this Type of engine (C70 - E) built between 1984-1986 - there just as well are some differences inside the gearbox as well. (shafts/ bearings/ spacers)

As I have three open engines, I am a bit confused ....

Let me try and sort this out.

this will be final treatment on the left side engine case.

I am surprised myself how much I like this :-0

I choose my surface treatment. Micro Bras-wire rotational brushing instead of polishing for the center casings and carburettor.

Not every Honda Aluminium cast is accepting polishing easily.

So I accidentally found that using a small Bras rotational power brush gives an interesting result :-)

More preparation on the engine casings for polishing. Sanding.

Allan Milliard is my Hero :-). Thanks Allan, for many inspiring engine builds.

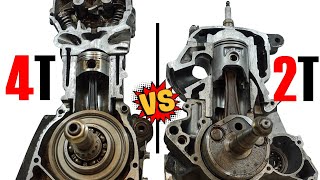

And no - I don't think I am capable to add cylinders,

for the time being I will feel well pleased with myself if I even get a standard engine running :-)

will I manage to free the piston rings??

..

Gearwheel carving, I think shall be what we call this activity :-).

..

Moving onto the gearbox...

Actually after I lost my nerve with the endless scraping I started tapping the gearwheels with a hammer - which was the cure surprisingly - the crust came of. The gearbox came out and apart.

And many hours of carving later we have some useable gearbox parts :-)

scraping for hours, trying to take out mangled timing gear and preparing to take out the Crank

separating engine cases, scraping tons of gue... #oil , #sand , #saltwater , #aluminium - #corrosion , #allgae , #algies , #barnacles , what is in that engine ??

after many heat cycles, lots of persuasion, hours of hammering, wedging and copious amounts of WD40 - the piston is finally out - in one piece :-)

Not sure if cylinder/ piston/ rings will even

move again together, but I sure will try my best to channel my inner "Stranded-in-the-Sahara-mechanic" ....

The following will be next:

a. stuck camshaft out

b. stuck ignition plate out

--------------

Some history of this build:

I have updated the mock-up

Basically I am seeing what needs done to achieve the seat height becoming lower than the rear tyre. (This being the central point that defines the look of this build)

So, so far I confirm:

1. Rear tyre as big as see possible

2. Front tyre as small as I see possible

3. Shorten the front fork 40 mm and extend wheelbase via external shock

unit by 40 mm

4. Extend Frame tube at lower end and reposition swing axis from bottom to

top of main frame tube and rearward (height wise this comes out about

the same but moves swing arm axis rearward considerably

5. I will need to section the tank..

6. ..and section the center body in 2 places by about a total of 70 mm in

height

7. Position 6 will then bring the seat height below the rear tyre height

8. In order to position the rear wheel center upwards I will need to extend the

rear swing arm and reposition the upper mounting axis of the rear suspension units

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: