Star Delta Starter Motor Connection Explained | star delta power and control wiring with timer

Автор: ONLINE ELECTRIC WORK

Загружено: 2024-09-05

Просмотров: 1468

Welcome to Online Electric Work.

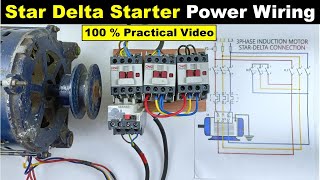

Today, we’re diving into the world of industrial motors to explore one of the most common methods used for starting three-phase induction motors – the Star-Delta Starter. Whether you’re an electrical engineer, a technician, or just curious about motor control, this video will break down how a Star-Delta Starter works, its components, and why it’s widely used in industries around the world.

What is a Star-Delta Starter:

A Star-Delta Starter is a type of motor starter used to reduce the high inrush current that occurs when a three-phase induction motor starts. When starting directly online, motors can draw up to 6-8 times their full load current, causing stress on both the electrical and mechanical components.

The Star-Delta Starter minimizes this by initially connecting the motor windings in a “Star” configuration, which reduces the voltage and current to a safe level. After the motor reaches a certain speed, it automatically switches to the “Delta” configuration, allowing the motor to run at its full capacity.

..

Components of a Star-Delta Starter

Main Contactor (KM1): This contactor connects the power supply to the motor.

Star Contactor (KM2): Used to connect the motor windings in a star configuration during the startup phase.

Delta Contactor (KM3): Switches the winding configuration from star to delta after a certain period.

Timer: A crucial part that ensures the motor switches from star to delta mode at the right moment.

Overload Relay (OLR): Protects the motor from overloads by disconnecting the power supply in case of excessive current.

..

How Does the Star-Delta Starter Work

step 1: Starting in Star Mode: When the motor is first started, the Main Contactor (KM1) and Star Contactor (KM2) are energized. This connects the motor windings in a star configuration, reducing the voltage to each winding by a factor of 1/1.732.

This significantly lowers the starting current to about 33% of what it would be if started directly in delta mode, thereby reducing stress on the motor and the electrical network.

. This significantly lowers the starting current to about 33% of what it would be if started directly in delta mode, thereby reducing stress on the motor and the electrical network.

Step 2: Transition to Delta Mode: After a preset time, typically around 10 seconds, the Star Contactor (KM2) de-energizes, disconnecting the star connection. At the same time, the Delta Contactor (KM3) is energized, connecting the windings in a delta configuration. The motor now receives the full line voltage and operates at full speed and torque.

..

Star-Delta Starters are widely used in applications like water pumps, compressors, conveyors, and large fans, where reducing the starting current and mechanical stress is crucial. It’s a cost-effective solution for starting medium to large motors that don't require high starting torque.

..

Your Queries:-

Star Delta Starter Motor Connection Explained

star delta power and control wiring with timer

How it works

star delta starter

star delta connection

star delta starter connection

star delta motor connection

star delta starter control circuit

delta connection

star delta connection diagram

motor starter

star delta

automatic star delta starter

3 phase motor connection

star delta starter control circuit diagram

star delta starter control wiring

delta star connection

star delta control wiring

star delta motor

star connection

..

#stardeltastarter #stardeltaconnection #stardelta #connectiondiagram #wiringcircuit #electrical #onlineelectricwork

Доступные форматы для скачивания:

Скачать видео mp4

-

Информация по загрузке: